Glued laminated timber (GLT)

Versatile, economical, and efficient

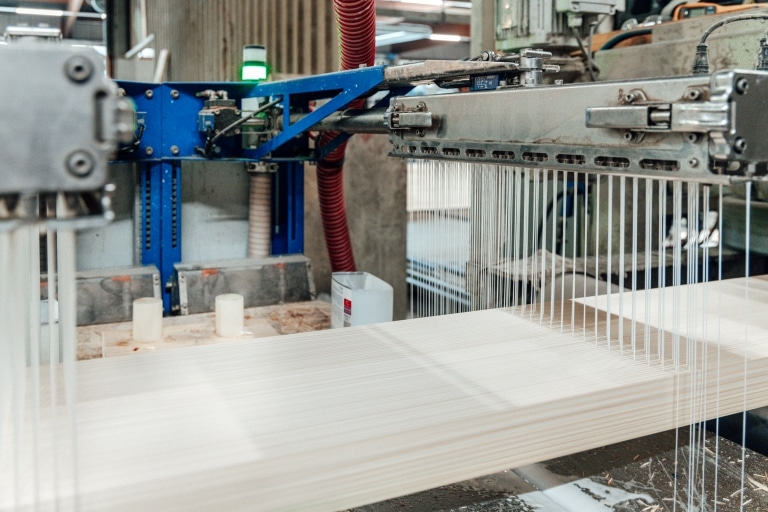

Glued laminated timber, or glulam, is the heart of timber engineering. Several layers of spruce wood are glued together in the direction of the grain and processed into customized glulam elements. Our glued laminated timber offers excellent static qualities. It is lightweight and retains its shape.

Advant-

ages

Trusses wider than 50 m? Trusses over 4 m long? Our glulam structures are manufactured to order with efficient material usage in mind, offering top load-bearing capacities.

Parallel chords, ridged roof trusses, fishbelly, bowstring trusses, timber frames, and single-pitch trusses: glulam support systems are prime examples of the unique character of timber engineering.

Your construction elements are accurately measured, produced to precise measurements down to the millimeter, equipped for assembly, reliably and punctually delivered, and assembled on site.

We only use domestic wood from ecologically managed forests. With our group’s own sawmill in Rohrbach an der Lafnitz, the wood supply is guaranteed as a resource. We know the origin of the wood we subsequently process into glulam structures. Thus, we cover the entire value chain from raw material to the finished project.

Wooden components have positive effects on the indoor climate. Wood is calming, smells good, and radiates warmth. The scent of wood has a calming effect on humans, and wood as a building material is actually warmer than other materials. You can test this by leaning against a wooden wall and then against a brick or concrete wall. You’ll notice the difference immediately! These properties create a necessary sense of well-being. Additionally, as a hygroscopic material, wood naturally regulates humidity. It absorbs or releases moisture, ensuring a pleasant indoor climate in your wooden building on hot summer days as well as frosty winter days.

Renewable trees store carbon and improve the CO2 balance. This is what makes wood unique and ecologically sustainable as a building material. By doing so, we make a positive contribution to reducing the global warming potential.

High fire resistance

Certainty of durability

The use of glulam allows for large-scale constructions without thermal bridges, provides excellent resistance in chemically aggressive environments, and offers several other lesser-known benefits. The material naturally exhibits high fire resistance, as the charred layer formed on its surface during a fire slows down or even prevents significant damage to the structural material. Consequently, timber structures do not fail spontaneously, and the burning speed and load-bearing capacity retention can be calculated.

Withstands significant seismic loads

Timber construction in earthquake-prone areas

The risk of earthquakes was largely overlooked in Central Europe until a few years ago. However, a dedicated European Standard has been developed to complement national regulations. When designing a building’s load-bearing system, it is crucial to consider the horizontal forces generated by earthquakes, which set entire buildings in motion. The lower weight of glulam structures compared to solid timber constructions is highly advantageous in this context. Rubner Holzbau’s experts analyze all relevant situational factors during the planning stage; carefully considering the floor plan, building height, load-bearing system type, bracing concept, selection of construction materials, mass distribution, and ductility of the load-bearing structures.

Quality & Standards

Certified and externally monitored

Wood, especially glulam, is a natural but predictable building material that offers nearly unlimited possibilities from a structural perspective. It allows for elegant and slender constructions that precisely meet static requirements while maintaining a commitment to design. To ensure compliance with high standards, both management processes and product manufacturing undergo continuous internal quality monitoring in our own laboratories. Additionally, external certification is carried out by accredited testing institutes.

From the use of PEFC-certified raw materials to project management according to ISO 9001 and production and element construction in compliance with RAL or Euronorm EN, our adherence to currently valid European product standards for glulam, and glulam EN 14080:2013, guarantees binding specifications for production, monitoring, strength classes, and other essential properties for construction and design. These standards are identical across Germany, Austria, and Italy. The certifying authorities for glulam production are the public and independent Materialprüfungsanstalt (MPA) of the University of Stuttgart (DE) and Holzforschung Austria (AT).