Technology and Production

From sawn timber to the finished product

DRYING

Moisture content according to area of application

Precise and careful drying of sawn timber is one of the most important steps in the production process since only dried timber provides long-term dimensional stability and is ready for further planing and gluing processes. Rubner Holzindustrie has 18 drying chambers and 4 drying channels and is thus able to dry 100 % of the sawn timber at in-house installations.

During the drying process, the sawn timber is dried until the required moisture content has been achieved. Our plants are equipped with heat recovery units. The electric power that is used for ventilators and regulating valves of the drying channels is mainly produced by photovoltaic plants, which are installed on the hall roofs.

The heat is generated in our in-house biomass heating plant, which is exclusively operated by using the bark.

PLANING UNIT

& SCANNER

Precision achieved by technology

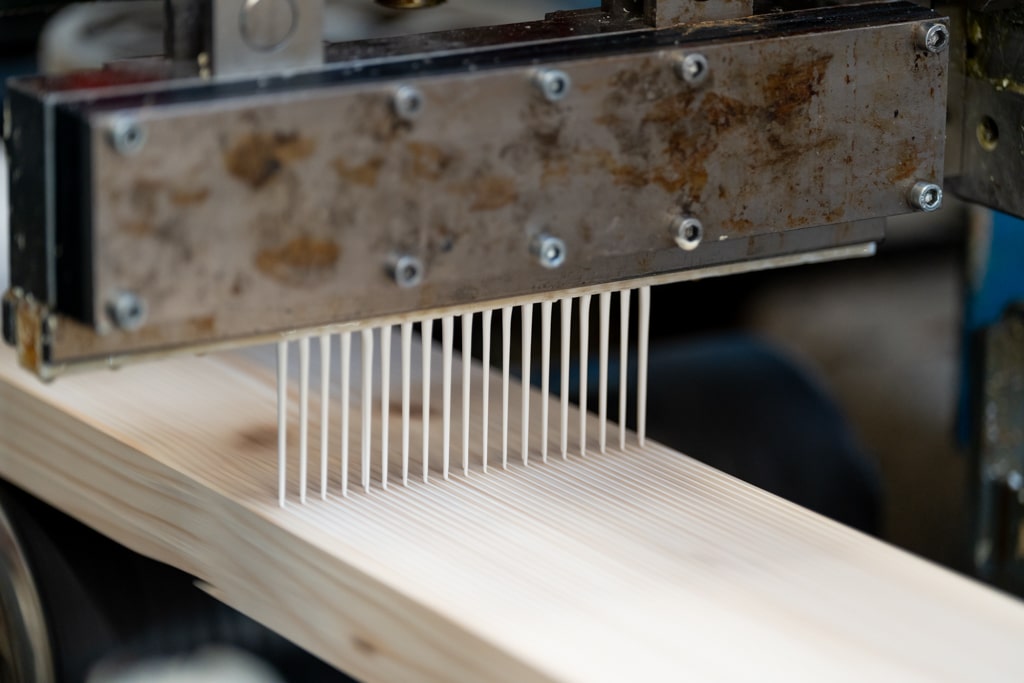

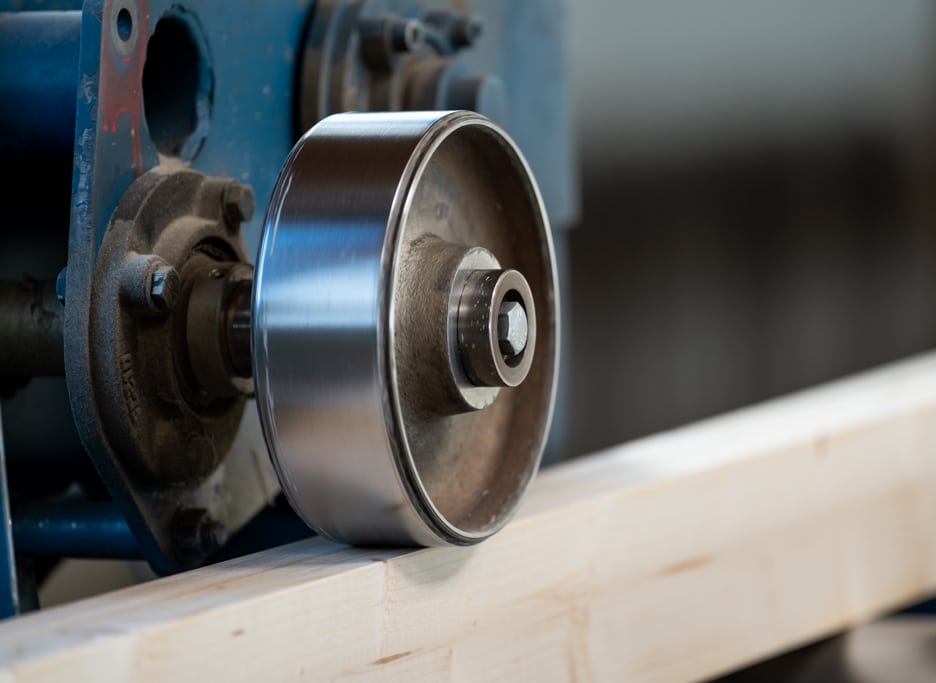

Prior to machine sorting, each single board undergoes different processes: moisture content measurement, board turning unit according to the annual rings, i.e. right side up, and planing unit. Once machine sorting has been concluded with the assistance of the Microtec Goldeneye 706, all non-desired board features are being marked.

A fully transparent and verifiable surface quality and stability profile is set up for each individual board. For those clients who also work with scanners from the market leading company Microtec, we can adopt order-specific sorting settings and apply them to the sorting process.

STORAGE

HALLS

Well-tempered storage Halls at our factory site

Rubner Holzindustrie has quite impressive storage facilities. The processed sawn timber is usually available in all common sizes and sorting categories and can thus be ordered at short notice ex-stock. We are therefore able to react to our customers’ requests quickly and flexibly.

In our well-tempered storage halls – securing perfect temperature and perfect moisture content – we store approximately 25,000 m3 of sawn timber in standard sizes for glulam beams production.