Sawn Timber

Ready for further processing

Glulam Beams, side cuts,

customer-specific cuttings,

solid construction timber

Rubner Holzindustrie offers a large variety of sawn timber products for further processing and refinement.

Sawn timber is obtained from spruce, fir, and pine. Spruce and fir are available in strength categories T14 and T26, pine is available in strength category C24.

Glulam Beams

Glulam beams offered by Rubner Holzindustrie are dried, pre-planed, machine graded and marked.

With a wood moisture content of 12 % (+/- 2 %) in the strength categories T14 and T26, these beams are perfectly suitable to be used in the timber engineering sector.

Our glulam beams are stored in well-tempered halls at our immediate factory site and delivery is made from our in-house storage facilities.

FORMATS

- Processing: Dried and marked

- Strength categories: T14 und T26

- Qualities: 1-/1-3 and 3-5

- Thickness: 36 mm und 44 mm

- Widths: 90 / 110 / 130 / 150 / 170 / 190 / 210 / 230 / 250 / 270 / 290 mm

- Lengths: 3 and 4m

- Processing: KD, planed

- Strength categories: C24

- Qualities: visible / non-visible areas

- Thickness: 44 mm

- Widths: 90 / 110 / 130 / 150 / 170 / 190 / 210 / 230 / 250 / 270 / 290 mm

- Lengths: 3 und 4m

Side cuts

Side cuts are used as raw product for packaging and construction purposes.

A considerable portion of side cuts is mechanically sorted and then used in the parquet floor industry or as raw material for cross laminated timber.

Exact processing and careful drying processes are the main prerequisite to secure the material’s further refinement by our clients.

FORMATS

- Processing: KD und ISPM

- Qualities: 3-5

- Thickness: 17 mm

- Widths: 75 / 95 / 115 mm

- Lengths: 3 m, 3,6 m und 4 m

- Processing: KD

- Qualities: 3-5

- Thickness: 22 mm, 23 mm

- Widths: 80 / 90 / 100 / 120 mm

- Lengths: 3 m und 4 m

- Processing: KD 12 %

- Qualities: 3-5

- thickness: 23 mm

- Widths: 120 / 130 / 140 / 150 / 160 mm

- Lengths: 3 m und 4 m

Availability upon request!

Customer-specific cuttings

An important focus of our business activities is placed on the production of glulam beams. However, we also fabricate – upon request – additional, customer-specific products and sizes, where we can fully display our know-how in the field of timber drying and machine sorting, always to the benefit or our clients.

Get in touch

Further products

PRECISE – RELIABLE – INNOVATIVE – VALUE ADDED

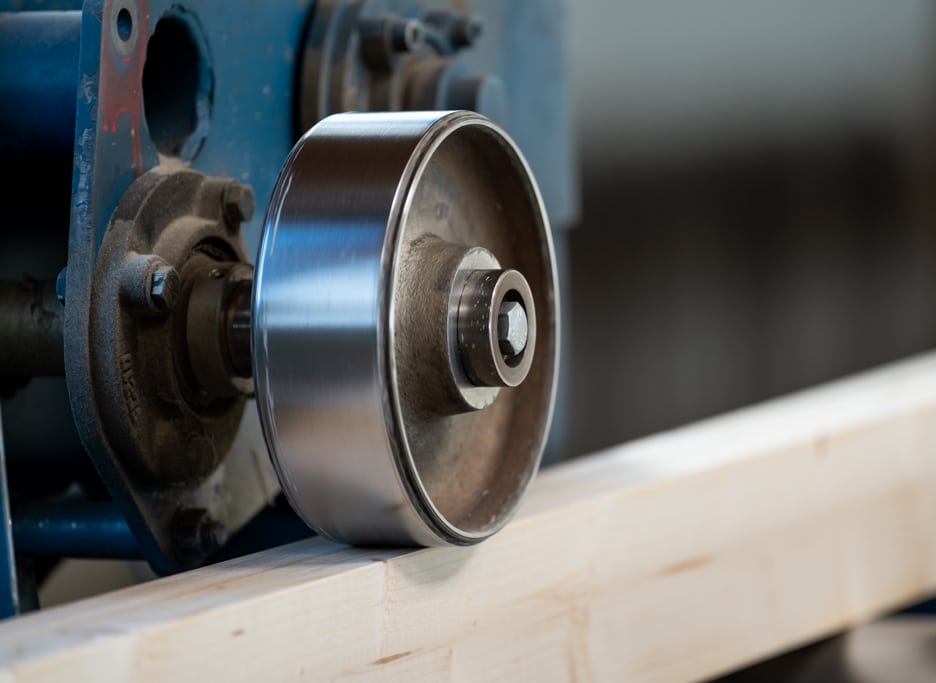

Ongoing investment in technologically innovative facilities guarantee a continuously high quality for our business partners – from sawn timber production to drying and finishing. Reliable grading of the raw material and machine-testing of our glulam beams to determine their strength is especially important for us. In addition, the Holzforschung Austria testing institute monitors our production and checks all our processes for compliance with the relevant standards. All our business partners benefit from this model, no matter whether they order small quantities or place a major order.