Full design freedom

Wall system timber frame construction

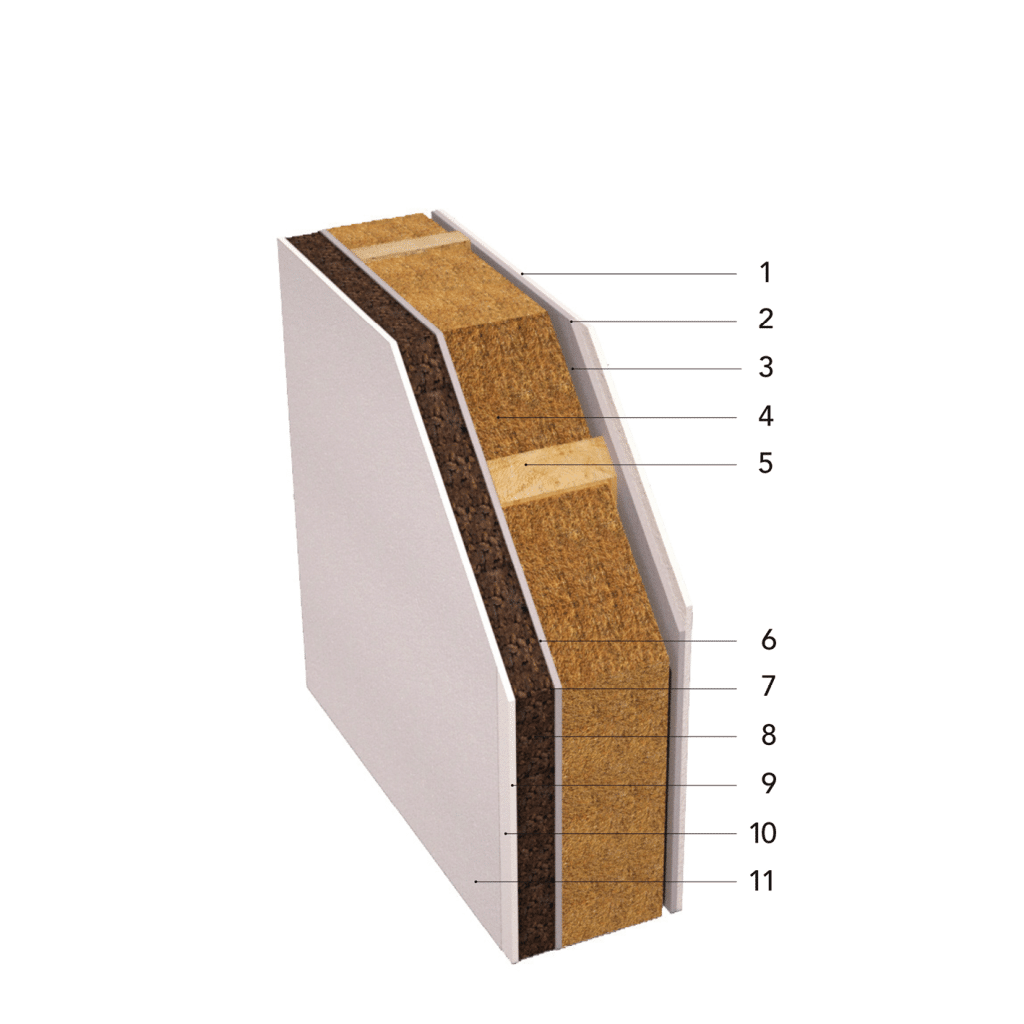

The beam structure of the walls and ceiling is individually made of wood in accordance with the architect’s design. Full planning freedom is available for this. The supporting framework consists of a timber frame made up of spruce elements. The intermediate spaces between the walls are filled completely with environment-friendly insulating material mounted on soft fiberboard. The soft fiberboard keeps its shape and prevents the insulation from settling, and therefore also prevents empty spaces, condensation and moisture. The inner side of the timber frame construction is then closed with gypsum fiberboard and plasterboard. This double cladding allows furniture to be placed at any desired point.

The outer wall is then finally closed with natural cork external thermal insulation. A base coat and finishing coat and/or alternative facade formwork are used to finish the house’s outer wall.

Thanks to the high prefabrication level of the Rubner Haus, the walls are already provided with windows, shade systems, doors and electrical as well as plumbing fixtures at the factory, provided that these items are included in the order.

Wall structure

Wooden timber frame

- Plasterboard, 13 mm

- Gypsum fiberboard (or wood panel), 13 mm

- Vapour barrier fleece

- Soft fiberboard, self-supporting, 140 – 220 mm

- Wood beam construction (DUOLAM), 160 – 240 mm

- Gypsum fiberboard, 15 mm

- Glue on cement base to fasten the external thermal insulation

- Corkboard, 80 mm

- Rendering with reinforcement mesh

- Mineral-based fine plaster

- Colour

Features in detail

- Wood as a natural construction material

- Components with open dimensions and optimum insulation

- Premium thermal insulation – both in winter and in summer

- Building physics designs with no diffusion barrier

- Contribution towards climate protection, permanent Co² storage

- Good heat insulation values through insulated elements

- Dry production at the plant irrespective of the weather

- Short construction time through high level of prefabrication